The basic designation of FAG bearing

Each FAG bearing has a designation that indicates the type, dimensions, tolerances and internal clearance. The FAG bearing nomenclature consist of prefix, designation, and suffix. The basic FAG bearing number indicates the FAG bearing type and width and diameter. Prefix and suffix of FAG bearing identify cage styles, seal types, internal clearances, etc.

FAG bearings that have the same standardised designation are interchangeable with each other. In the case of separable bearings, it cannot always be ensured that individual parts with the same origin can be interchanged with each other. In Germany, the FAG bearing designations are standardised in DIN 623-1. These designations are also used in many other countries. Please refer to SKF bearing designation.

FAG bearing designation is identified as the table below:

| Prefix | Basic FAG bearing number | Suffix |

The designation for the FAG bearing series comprises numbers and letters or letters and numbers. It indicates the type of FAG bearing, the diameter series and, in many cases, the width series too. The basic designation contains the symbols for the FAG bearing series and the bearing bore.

The code of FAG bearing type

- 0: Double row angular contact ball bearing

- 1: Self-aligning ball bearing

- 2: Spherical roller bearing, spherical roller thrust bearing

- 3: Tapered roller bearing

- 4: Double row deep groove ball bearing

- 5: Axial deep groove ball bearing

- 6: Single row deep groove ball bearing

- 7: Single row angular contact ball bearing

- 8: Axial cylindrical roller bearing

- C: Toroidal roller bearing

- N: Single row cylindrical roller bearing

- NN: Double row cylindrical roller bearing

- QJ: Four point contact bearing

The diameter and width series

Width and diameter series are described using numbers. In the case of radial bearings in accordance with DIN 616 and ISO 15, these are as follows:

- For width series, the numbers 8, 9, 0, 1, 2, 3, 4, 5, 6, 7

- For the designation of diameter series, the numbers 7, 8, 9, 0, 1, 2, 3, 4, 5

Dimension series for FAG radial bearings (excluding tapered roller and needle roller bearings)

| Width series – increase in cross-sectional width | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||

| Diameter series – increase in cross-sectional height | 5 | – | – | – | – | – | – | – | – | – | – |

| 4 | – | – | 04 | – | 24 | – | – | – | – | – | |

| 3 | 83 | – | 03 | 12 | 23 | 33 | – | – | – | – | |

| 2 | 82 | – | 02 | 12 | 22 | 32 | 42 | 52 | 62 | – | |

| 1 | – | – | 01 | 11 | 21 | 31 | 41 | 51 | 61 | – | |

| 0 | – | – | 00 | 10 | 20 | 30 | 40 | 50 | 60 | – | |

| 9 | – | – | 09 | 19 | 29 | 39 | 49 | 59 | 69 | – | |

| 8 | – | – | 08 | 18 | 28 | 38 | 48 | 58 | 68 | – | |

| 7 | – | – | – | 17 | 27 | 37 | 47 | – | – | – | |

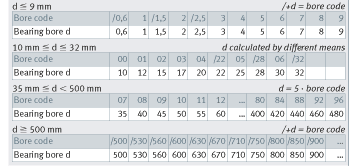

The FAG bearing bore code

The bore code is derived from the diameter d of the FAG bearing bore; with a factor of 5 or the addition of an oblique.

For d < 10 mm, the bore diameter is stated in the basic designation

For certain FAG bearing types, the bearing bores are stated directly or in an encoded form in accordance with DIN 623-1. Up to d < 10 mm, the bearing bore diameter is specified in the dimension-specific part of the designation (basic designation) directly as a number indicating the diameter.

For example FAG deep groove ball bearing 608, bore diameter = 8mm.

The bore code describes the FAG bearing bore from d ≧ 10 mm

For nominal dimensions d ≧ 10 mm to d < 500 mm, the diameter is described by means of a bore code.

For bores from 10 mm to 17 mm, the following applies:

| d = 10 mm, | bore code 00 |

| d = 12 mm, | bore code 01 |

| d = 15 mm, | bore code 02 |

| d = 17 mm, | bore code 03. |

For all FAG rolling bearings in the range from d = 20 mmto d = 480 mm (excluding double direction axial bearings), the bore code is formed by dividing the dimension of the bearing bore by 5.

For example: FAG 7314-B-TVP-UA Bearing, bore d = 70 mm divided by 5 (70:5), bore code = 14.

From d > 480 mm

From d > 480 mm, the unencoded bore diameter is given with an oblique after the bearing series, e.g. FAG 232/500-BEA-XL-MB1 bearing with bore diameter d = 500 mm.

Intermediate sizes

The intermediate sizes, such as bore diameter d = 22, 28 and d = 32 mm for example, are also given with an oblique as /22, /28 and /32.

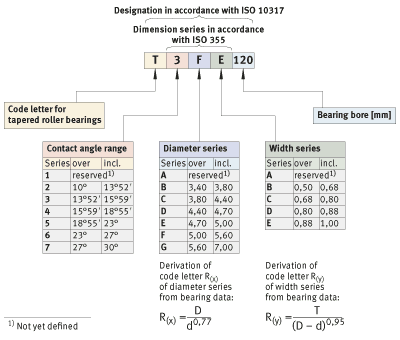

Designations of FAG metric tapered roller bearings

The above figure describes as an example the structure of the designation for a FAG metric tapered roller bearing (dimension series to ISO 355, designation to ISO 10317). The 3 indicates the contact angle range. The first letter (F in this case) indicates a diameter series. Each diameter series has a certain ratio D/d (outside diameter to bore diameter). The second letter (E in this case) indicates a width series. Each width series has a certain ratio of bearing width T to the height of the bearing cross-section. The addition of the letter T (for tapered roller bearing) at the start and a three-digit number at the end for the bearing bore diameter in mm (in this case 120) gives the complete designation of a FAG tapered roller bearing.

FAG bearing prefix

The prefix normally identifies individual FAG bearing parts of complete bearings (in certain cases, this may also be part of the basic designation)

| Prefix | Description of prefix |

|---|---|

| GS | Single part housing locating washer |

| K | axial cylindrical roller and cage assembly |

| WS | shaft locating washer |

| LS | bearing washers, alternatively for shaft and housing locating washer |

FAG bearing suffix

FAG deep groove ball bearing suffixes

Suffixes and corresponding descriptions, FAG single row deep groove ball bearings

| Suffix | Description of suffix | |

|---|---|---|

| C | Deep groove ball bearing, Generation C | Standard |

| M | Solid brass cage, ball-guided | |

| MA | Solid brass cage, guided on outer ring rib | Available by agreement |

| MB | Solid brass cage, guided on inner ring rib | |

| C2 | Radial internal clearance C2 (smaller than normal) | Available by agreement |

| C3 | Radial internal clearance C3 (larger than normal) | |

| C4 | Radial internal clearance C4 (larger than C3) | |

| CM | Radial internal clearance more closely toleranced than normal |

|

| 2BRS | Non-contact seal on both sides (labyrinth seal) | Standard for Generation C |

| 2HRS | Contact seal on both sides (lip seal) | Standard for Generation C |

| 2RSR | Contact seal on both sides (lip seal) | Standard |

| 2RZ | Non-contact seal on both sides (rubberised gap seal) |

Standard |

| 2Z | Non-contact sealing shield on both sides (sheet metal gap seal) |

Standard |

| BRS | Non-contact seal on one side (labyrinth seal) | Available by agreement |

| ELS | Contact seal on one side (lip seal) | Available by agreement for Generation C |

| 2ELS | Contact seal on both sides (lip seal) | Available by agreement for Generation C |

| RSR | Contact seal on one side (lip seal) | Available by agreement |

| RZ | Non-contact seal on one side (rubberised gap seal) | Available by agreement |

| TVH | Solid cage made from glass fibre reinforced polyamide PA66 | Available by agreement |

| Y | Sheet brass cage | Available by agreement |

| Z | Non-contact sealing shield on one side (sheet metal gap seal) |

Available by agreement |

| S0 | Dimensionally stabilised bearing for operating temperatures up to +150 °C |

Available by agreement |

| S1 | Dimensionally stabilised bearing for operating temperatures up to +200 °C |

Available by agreement |

| S2 | Dimensionally stabilised bearing for operating temperatures up to +250 °C |

Available by agreement |

Suffixes and corresponding descriptions, FAG double row deep groove ball bearings

| Suffix | Description of suffix | |

|---|---|---|

| B | Modified internal construction | Standard |

| TVH | Solid cage made from glass fibre reinforced polyamide PA66 | Standard |

FAG angular contact ball bearing suffixes

Suffixes and corresponding descriptions

| Suffix | Description of suffix | |

|---|---|---|

| B | Modified internal construction, nominal contact angle α = 40° |

Standard |

| JP | Sheet steel cage | Standard, dependent on bore code |

| MP | Solid brass cage | |

| TVH, TVP | Solid cage made from glass fibre reinforced polyamide PA66 | |

| P5 | Bearing in tolerance class 5 | Special design, available by agreement |

| 2RS | Contact seal on both sides (lip seal) | Standard |

| UA | Universal design for fitting in pairs, bearing pair has a small axial internal clearance in O and X arrangement |

|

| UB | Universal design for fitting in pairs, bearing pair has a smaller axial internal clearance in O and X arrangement than in UA |

|

| UH | Universal design for fitting in pairs, bearing pair has a high preload in O and X arrangement |

Available by agreement |

| UL | Universal design for fitting in pairs, bearing pair has a light preload in O and X arrangement |

Standard |

| UM | Universal design for fitting in pairs, bearing pair has a moderate preload in O and X arrangement |

Available by agreement |

| UO | Universal design for fitting in pairs, bearing pair is clearance-free in O and X arrangement |

Standard |

| XL | X-life bearing, dependent on bore code and bearing type |

Standard |

FAG four point contact bearing suffixes

| Suffix | Description of suffix | |

|---|---|---|

| C2 | Axial internal clearance C2 (smaller than normal) |

Special design, available by agreement |

| C3 | Axial internal clearance C3 (larger than normal) |

|

| C4 | Axial internal clearance C4 (larger than C3) |

|

| MPA | Solid brass cage, guided on outer ring | Standard, cage material dependent on bearing series and bore code |

| TVP | Solid cage made from glass fibre reinforced polyamide PA66 |

|

| XL | X-life bearing | Standard, dependent on bore code and bearing type |

| N2 | Two retaining slots in outer ring | Standard for larger bearings |

FAG self-aligning ball-bearing suffixes

| Suffix | Description of suffix | |

|---|---|---|

| C3 | Radial internal clearance C3 (larger than normal) |

Standard for bearings with tapered bore |

| CN | Radial internal clearance CN (normal) |

Special design for bearings with tapered bore, available by agreement |

| K | Tapered bore | Standard |

| M | Solid brass cage | Standard, cage material dependent on bearing series and bore code |

| TVH | Solid cage made from glass fibre reinforced polyamide PA66 |

|

| 2RS | Contact seal on both sides | Dependent on bearing series |

FAG cylindrical roller bearing suffixes

| Suffix | Description of suffix | |

|---|---|---|

| C3 | Radial internal clearance C3 (larger than normal) | Available by agreement |

| C4 | Radial internal clearance C4 (larger than C3) | |

| C5 | Radial internal clearance C5 (larger than C4) | |

| E | Increased capacity design | Standard |

| EX | Increased capacity design, design modified in accordance with standard (parts from these bearings must not be interchanged with parts from bearings of the same size of the previous design E) |

|

| JP3 | Sheet steel window cage, single-piece, roller-guided | Available by agreement |

| J30P | Black oxide coated (Durotect B) | |

| MPAX | Solid brass cage, single-piece, rib-guided on the outer ring | |

| MPBX | Solid brass cage, single-piece, rib-guided on the inner ring | |

| M1 | Solid brass cage, two-piece, roller-guided | Standard |

| M1A | Solid brass cage, two-piece, rib-guided on the outer ring | Available by agreement |

| M1B | Solid brass cage, two-piece, rib-guided on the inner ring | |

| TB | Bearing with increased axial load carrying capacity (toroidal crowned design) | Standard, dependent on bearing size |

| TVP2 | Solid window cage made from glass fibre reinforced polyamide PA66 | Standard |

| XL | X-life bearing | |

FAG tapered roller bearing suffixes

| Suffix | Description of suffix |

|---|---|

| A | Modified internal construction (excluding bearings to ANSI/ABMA) |

| B | Increased contact angle (for bearings to DIN) |

| DF-A..-.. | Two tapered roller bearings matched in an X arrangement, with an intermediate ring between the outer rings. Axial internal clearance between .. and .. in μm |

| X | External dimensions matched to international standards (for bearings to DIN) |

| XL | X-life |

FAG tapered roller bearing for special applications. Special designs, available by agreement

| Suffix | Description of suffix |

|---|---|

| DB-A..-.. | Two tapered roller bearings matched in an O arrangement, with an intermediate ring between the outer rings and the inner rings, axial internal clearance between .. and .. in μm |

| DT | Two tapered roller bearings matched in a tandem arrangement, with an intermediate ring between the outer rings |

| P5 | Bearing in tolerance class 5 |

FAG barrel roller bearing suffixes

| Suffix | Description of suffix | |

|---|---|---|

| C2 | Radial internal clearance C2 (smaller than normal) |

Special design, available by agreement |

| C3 | Radial internal clearance C3 (larger than normal) |

Normally used for bearings with tapered bore, available by agreement for bearings with cylindrical bore |

| C4 | Radial internal clearance C4 (larger than C3) |

Special design, available by agreement |

| CN | Radial internal clearance CN (normal) |

Standard for bearings with cylindrical bore, available by agreement for bearings with tapered bore |

| K | Tapered bore, taper 1:12 | Standard |

| MB | Solid brass cage, guided on inner ring | Standard, cage material dependent on bore code |

| TVP | Solid cage made from glass fibre reinforced polyamide PA66 |

|

FAG spherical roller bearing suffixes

| Suffix | Description of suffix | |

|---|---|---|

| A-MA, AS-MA |

Two brass cages, guidance on the outer ring, inner ring with two lateral retaining ribs and one central rib |

Standard combinations |

| B-FB1 | One steel cage, guidance on the inner ring, inner ring with two lateral retaining ribs and one central rib |

|

| BE-XL | Two sheet steel cages, surface hardened, guidance on inner ring, X-life |

|

| BE-XL-JPA | Two sheet steel cages, surface hardened, guidance on the outer ring, X-life |

|

| BEA-XL-MB1 | One brass double comb cage, guidance on the inner ring, inner ring with two lateral retaining ribs, X-life |

|

| E1-XL | Two sheet steel cages, surface hardened or coated, guidance on the outer ring, X-life |

|

| E1-XL-TVPB | Two window cages made from glass fibre reinforced polyamide, guidance on the inner ring, X-life | |

| E1A-XL-M | One brass double comb cage, guided by rollers, inner ring with two lateral retaining ribs, X-life |

|

| MB, B-MB |

Two brass cages, guidance on the inner ring, inner ring with two lateral retaining ribs and one central rib |

|

| MA1 | One brass cage, guidance on the outer ring, inner ring with two lateral retaining ribs and one central rib |

|

| 2RSR | Contact seal (lip seal) on both sides with sheet steel reinforcement, made from nitrile rubber (NBR); grease fill level 25% to 40%, filled with high-pressure grease |

Standard |

| 2VSR | Contact seal (lip seal) on both sides with sheet steel reinforcement, made from fluoro rubber (FKM); grease fill level 60% to 100%, filled with high-temperature grease |

|

| C2 | Radial internal clearance C2 (smaller than normal) | Available by agreement |

| C3 | Radial internal clearance C3 (larger than normal) | |

| C4 | Radial internal clearance C4 (larger than C3) | |

| H40 | Without lubrication groove and lubrication holes | |

| H40CA | 6 lubrication holes in the outer ring | |

| H40AB | 6 lubrication holes in the inner ring | |

| H40AC | 6 lubrication holes and one lubrication groove in the inner ring |

|

| H78(*) | 3 uniformly distributed threaded holes in one end face of the outer ring (* weight-oriented module letter, please contact us) |

|

| H151 | One 45° retaining slot in the outer ring | |

| H151B | One 15° retaining slot in the outer ring | |

| K | Tapered bore, taper 1:12 | |

| K30 | Tapered bore, taper 1:30 | |

| P5 | Dimensional and running accuracy in accordance with ISO tolerance class 5 |

|

| S | Lubrication groove and lubrication holes in outer ring | |

| SY | 3 lubrication holes in the outer ring, no lubrication groove | |

| T41A | For oscillating load with restricted diameter tolerances, radial internal clearance C4 | |

| T41D | For oscillating load with restricted diameter tolerances, radial internal clearance C4, bore with thin chromium coating |

|

| W209B | Inner ring made from case hardening steel | |

| XL | X-life bearing | |

FAG thrust ball bearing suffixes

FAG axial deep groove ball bearings suffixes

| Suffix | Description of suffix | |

|---|---|---|

| MP | Solid brass cage, ball-guided | Standard |

| P5 | Bearing in tolerance class 5 | Special design, available by agreement |

| P6 | Bearing in tolerance class 6 | |

FAG thrust roller bearing suffixes

FAG axial spherical roller bearings suffixes

| Suffix | Description of suffix | |

|---|---|---|

| E1 | Increased capacity design | Standard |

| MB | Solid brass cage | |

| N1 | One retaining slot in the housing locating washer |

|

| N2 | Two retaining slots offset by 180° in the housing locating washer |

|

| THI | 3 uniformly distributed threaded holes in one end face of the shaft locating washer |

|

| THIE | 3 uniformly distributed threaded holes in one end face of the shaft locating washer, incl. suitable eye bolts |

|

| THO | 3 uniformly distributed threaded holes in one end face of the housing locating washer |

|

| THOE | 3 uniformly distributed threaded holes in one end face of the housing locating washer, incl. suitable eye bolts |

|

| XL | X-life bearing | |

source:https://www.nodeshk.com/fag/art/fag-bearing-designation.html